iBiotec

Formulator & Manufacturer

of technical cleaning solvents

for manufacturers and applicators of resins

and composite resins

Alternative solvents and substitutes

for ketones, chlorinated solvents,

NMP, NEP and other CMRs

Polyurethane resins are also called carbamate resins.

This category includes all compounds produced by the reaction of an isocyanate with an alcohol: short-chain or long-chain diols or polyols.

They can be obtained by polycondensation or polyaddition.

Polyurethanes can provide many technical advantages, according to their method of use and applications, at low pressure or high pressure.

High pressure

|

In the form of expanded foam, polyurethane foams are widely used for their exceptional thermal insulation properties, their adherence, their flotation properties, and their ability to fill voids via simultaneous projection. |

|

CLEANING SOLVENT FOR NON-CURED

or FRESHLY POLYMERISED RESINS

POLYESTER, POLYURETHANE,

EPOXY and Bis-GMA

ALTERNATIVE SOLVENT TO NMP AND NEP

NO HAZARD OR WARNING PICTOGRAM

(CLP 1272 GHS Regulation)

iBiotec FAST CLEAN MANGO 90

Not classified flammable

Guaranteed free of hazardous, harmful,

irritating or sensitising substance

Slightly volatile

Reduced consumption

SMP optimisation

Solvent Management Plan

(IED Directive)

ODP 0

GWP 0

Easily and quickly biodegradable

TYPICAL PHYSICAL-CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour |

Visual |

Yellow |

- |

|

Smell |

Olfactory |

Slight, mango |

- |

|

Density at 25°C |

NF EN ISO 12185 |

1090 |

kg/m3 |

|

Refraction index |

ISO 5661 |

1.4450 |

- |

|

Freezing point |

ISO 3016 |

-15 |

°C |

|

Water solubility |

- |

>40 |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

1.7 |

mm²/s |

|

Acid index |

EN 14104 |

<1 |

mg(KOH)/g |

|

Iodine index |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

<1 |

% |

|

Residue after evaporation |

NF T 30-084 |

<0.1 |

% |

|

PERFORMANCE CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

>180 |

- |

|

Evaporation speed |

- |

>3 |

hours |

|

Evaporation rate nBuAC=1 |

NF T 30.30 |

1.4 |

Quotient |

|

Evaporation rate DEE=1 |

DIN 53.170 |

nm |

Quotient |

|

Surface tension at 20°C |

ISO 6295 |

27.7 |

dyne/cm |

|

Copper blade corrosion 100 h at 40°C |

ISO 2160 |

1b |

Rating |

|

Aniline point |

ISO 2977 |

nm |

°C |

|

FIRE SAFETY CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flashpoint (closed cup) |

NF EN 22719 |

90 |

°C |

|

Autoignition point |

ASTM E 659 |

>200 |

°C |

|

Lower Explosive Limit |

NF EN 1839 |

2.6 |

% (volume) |

|

Upper Explosive Limit |

NF EN 1839 |

28.5 |

% (volume) |

|

Explosive, oxidising agent, flammable, highly or extremely flammable substance content |

CLP Regulation |

0 |

% |

|

TOXICOLOGICAL CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine index |

NF ISO 6885 |

<2 |

- |

|

Peroxide index |

NF ISO 3960 |

<5 |

meq(O2)/kg |

|

TOTOX (anisidine index+2x peroxide index) |

- |

nm |

- |

|

CMR, irritant and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

ENVIRONMENTAL CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Water hazard |

WGK Germany |

1 without hazard for water |

class |

|

Primary CEC biodegradability 21 days at 25°C |

L 33 T82 |

>80 |

% |

|

OECD easy biodegradability 301 A over 28 days Disappearance of COD |

ISO 7827 |

>80 |

% |

|

OECD easy and ultimate biodegradability 301 D over 28 days Biodegradation at 67 days |

MITI amended |

>70 |

% |

|

Bioaccumulation n-octanol water sharing index |

OECD 107 |

-1.35 |

KOW log |

|

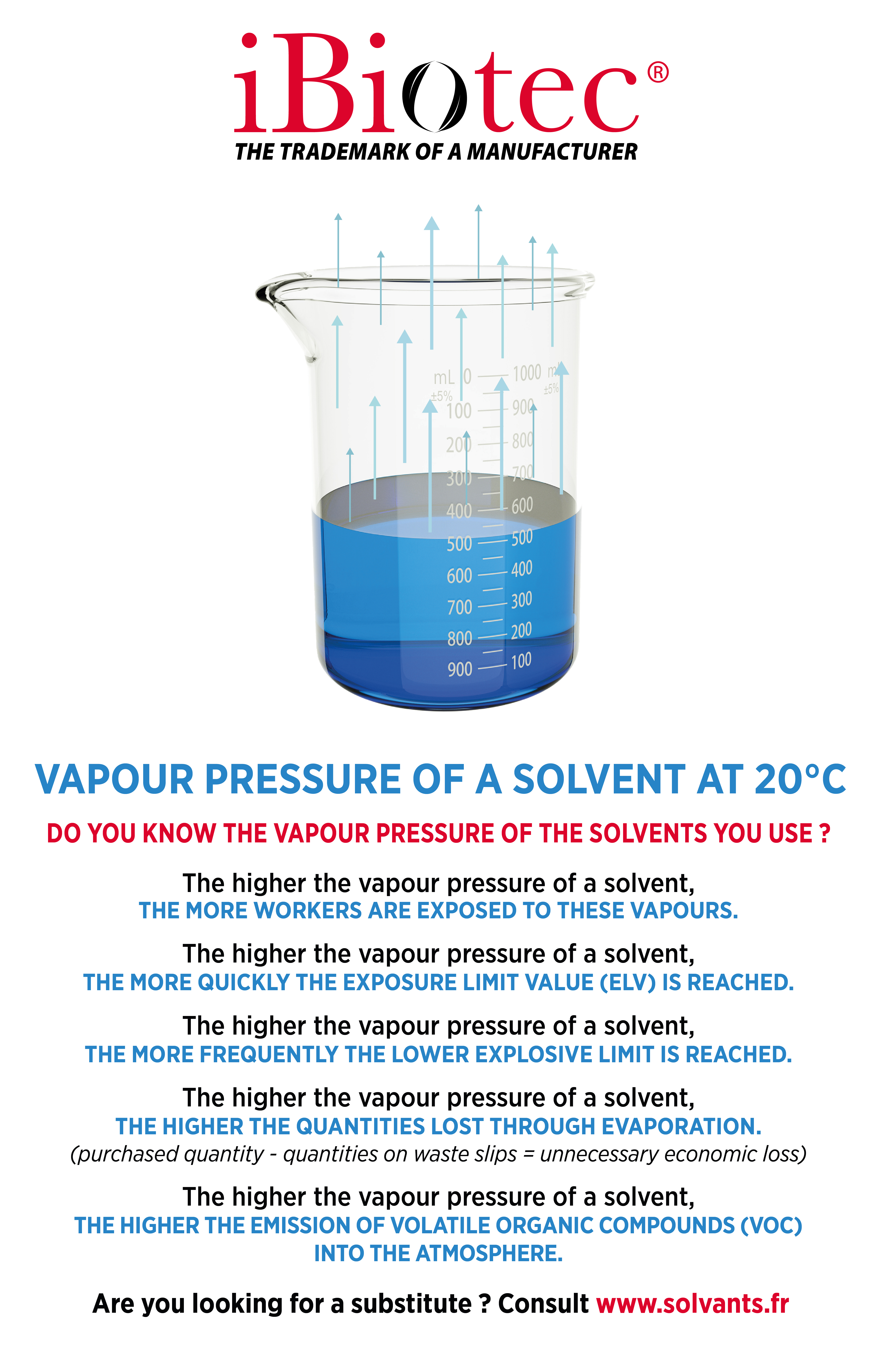

Steam pressure at 20°C |

- |

<0.1 |

hPa |

|

VOC content (Volatile Organic Compounds) |

- |

Unmeasured carbon content |

% |

|

Total halogen content (Chlorine Fluorine Bromine) |

Bomb calorimeter GC MS |

0 |

% |

|

Benzene content |

LPCH |

0 |

% |

|

Aromatic solvent content |

LPCH |

0 |

% |

|

Environmentally-hazardous substance content |

- |

0 |

% |

|

Content of compounds with GWP |

- |

0 |

% |

|

Content of compounds with ODP |

- |

0 |

% |

|

Carbon assessment, life cycles analysis. |

ISO 14040 |

6.40 |

Kg carbon equivalent |

nm: not measured or cannot be measured

Cleaning of spraying materials including simultaneously

Cleaning of Blow'In materials for polyester/fibreglass flock spraying

Dissolving and cleaning of freshly polymerised polyurethane foams

Insulation, sealing, repair and filling PU