iBiotec® FAST CLEAN PU 110

POLYURETHANE CLEANING SOLVENT

RINSING FLUID FOR POLYURETHANE CASTING HEADS

ON LOW PRESSURE MACHINE

AGRO-SOLVENT

|

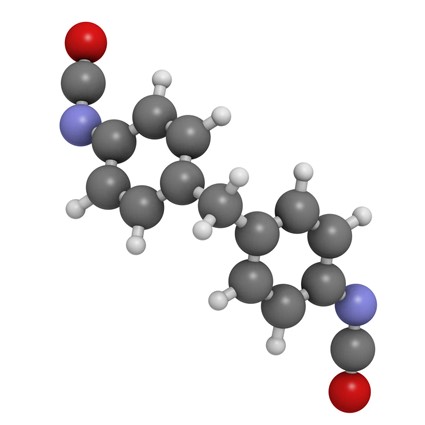

Alternative solvent to methylene chloride with no modification to machine settings or cycle times. iBiotec® FAST CLEAN PU 110 is used to rinse RIM compact polyurethanes, type TDI and MDI, including with very short pot life. iBiotec® FAST CLEAN PU 110 is mainly made up of plant material by-products and materials found naturally in the environment. iBiotec® FAST CLEAN PU 110 reduces organic vapour emissions to zero. iBiotec® FAST CLEAN PU 110 is not flammable. Its high flashpoint means that it can be used hot or cold in total safety. iBiotec® FAST CLEAN PU 110 contains no substance which is hazardous for health. Its constituent parts are not toxic, carcinogenic, mutagenic, toxic to reproduction, harmful, irritating, sensitising or corrosive. |

|

TECHNICAL DATA SHEET

iBiotec® FAST CLEAN PU 110

|

|

No hazard pictogram CLP 1272/2008 1079/2016

Alternative solvent to methylene chloride with no modification to machine settings or cycle times.

ELIMINATION OF POLYURETHANES

iBiotec® FAST CLEAN PU 110 is the ideal solvent for eliminating polyurethanes in mixing rooms and casting heads of low pressure removal machines.

It is appropriate for the elimination of compact resins, foams and RIM. It is also an excellent cleaning agent for eliminating burrs on polyurethane joints used in mirror glass and glass and for cleaning removal tools such as spatula and guns.

iBiotec® FAST CLEAN PU 110 is also used to clean resin and paint manufacturing tanks; it also eliminates pigments and colour pastes.

COMPACT POLYURETHANE REMOVAL MACHINE

The washing cycle after injection of polyurethanes is as follows:

- Air blowing for 10 seconds;

- Injection of iBiotec®FAST CLEAN PU 110 for 3 seconds;

- Air blowing for 30 seconds;

- Injection in investment casting to eliminate the residues totally.

These times are given as a guide and can vary according to the nature of the polyurethanes.

During the washing cycle, the mixing chamber can be positioned above a metal keg fitted with a funnel to recover the iBiotec® FAST CLEAN PU 110 effluents.

These can be filtered (metal filter of 6/10th millimetre); the mix can also be allowed to settle for 24 hours.

iBiotec® FAST CLEAN PU 110 can be reused four times in succession.

iBiotec® FAST CLEAN PU 110 can also strip by soaking turbines in which polyurethane residues have polymerised, especially foam residues which have a very short reaction time.

CREATING DOUBLE GLAZING JOINTS

Spatula are cleaned simply by soaking and guns by circulating.

FORMULATION IMPROVING SAFETY

iBiotec® FAST CLEAN PU 110 is not flammable. Its high flashpoint means that it can be used hot or cold in total safety.

iBiotec® FAST CLEAN PU 110 contains no hazardous substance for health (Order of 9 November 2004): its constituent parts are not toxic, carcinogenic, mutagenic, toxic to reproduction, harmful, irritating, sensitising or corrosive.

iBiotec® FAST CLEAN PU 110 does not emit hazardous vapours and is not toxic or harmful through contact with the skin.

ENVIRONMENTALLY-FRIENDLY FORMULATION

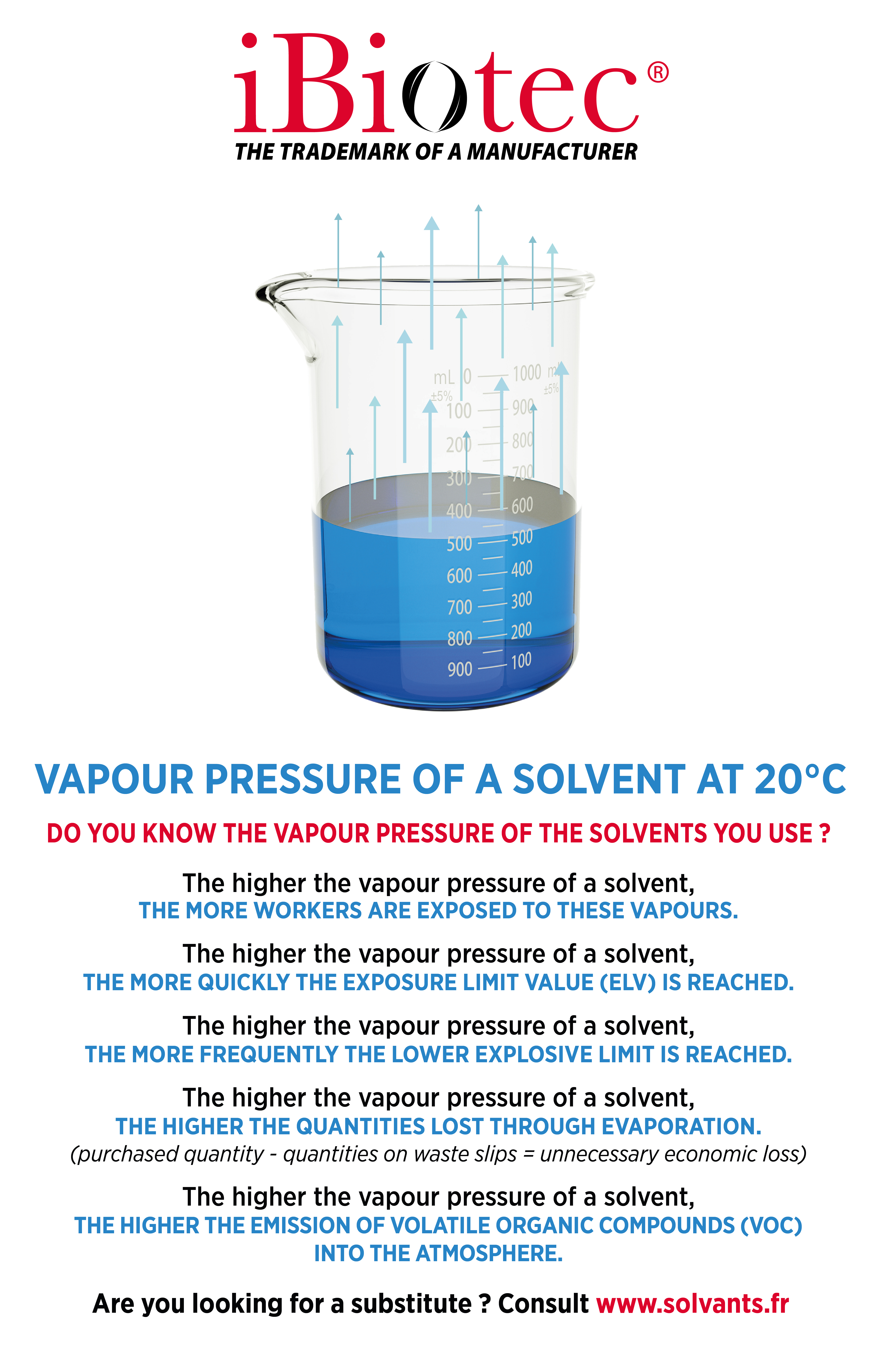

iBiotec® FAST CLEAN PU 110 is virtually non-volatile (1000 times less than methylene chloride).

In practical terms, iBiotec® FAST CLEAN PU 110 reduces organic vapour emissions to zero.

Polyurethane casting workshops, double glazing manufacturing establishments and manufacturers of elastomers, paints and colour pastes can therefore comply without difficulty with the VOC emission limits (Order of 29 May 2000) during the cleaning stages.

iBiotec® FAST CLEAN PU 110 does not emit any hazardous substance for the ozone layer or participating in global warming.

TYPICAL PHYSICAL-CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour |

Visual |

Yellow |

- |

|

Smell |

Olfactory |

Without |

- |

|

Density at 25°C |

NF EN ISO 12185 |

968 |

kg/m3 |

|

Refraction index |

ISO 5661 |

1,4480 |

- |

|

Freezing point |

ISO 3016 |

-4 |

°C |

|

Water solubility |

- |

partial |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

3.0 |

mm²/s |

|

Acid index Ia |

EN 14104 |

<1 |

mg(KOH)/g |

|

Iodine index |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

<0.1 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

PERFORMANCE CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

>200 |

- |

|

Evaporation speed |

- |

>6 |

hours |

|

Surface tension at 20°C |

ISO 6295 |

32.0 |

dyne/cm |

|

Copper blade corrosion 100 h at 40°C |

ISO 2160 |

1a |

Measured value |

|

Aniline point |

ISO 2977 |

nm |

°C |

|

FIRE SAFETY CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flashpoint (closed cup) |

NF EN 22719 |

95 |

°C |

|

Autoignition point |

ASTM E 659 |

>270 |

°C |

|

Lower Explosive Limit |

NF EN 1839 |

2,6 |

% (volume) |

|

Upper Explosive Limit |

NF EN 1839 |

28,5 |

% (volume) |

|

Explosive, oxidising agent, flammable, highly or extremely flammable substance content |

CLP Regulation |

0 |

% |

|

TOXICOLOGICAL CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine index |

NF ISO 6885 |

<6 |

- |

|

Peroxide index |

NF ISO 3960 |

<10 |

meq(O2)/kg |

|

TOTOX (anisidine index+2x peroxide index) |

- |

<26 |

- |

|

CMR, irritant and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous compounds, CMR, irritants, corrosive at 100°C |

GC-MS |

Without |

% |

|

ENVIRONMENTAL CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Water hazard |

WGK Germany |

1 without hazard for water |

class |

|

Primary CEC biodegradability 21 days at 25°C |

L 33 T82 |

>80 |

% |

|

OECD easy biodegradability 301 A over 28 days Disappearance of COD |

ISO 7827 |

>80 |

% |

|

OECD easy and ultimate biodegradability 301 D over 28 days Biodegradation at 67 days |

MITI amended |

>90 |

% |

PRESENTATIONS

|

Bidon 20 L

|

Drum 200 L

|

GRV 1000 L

|

|

|

|