COMPACT POLYURETHANES

Substitute solvents for

rinsing, stripping and inerting

in casting, by low pressure injection

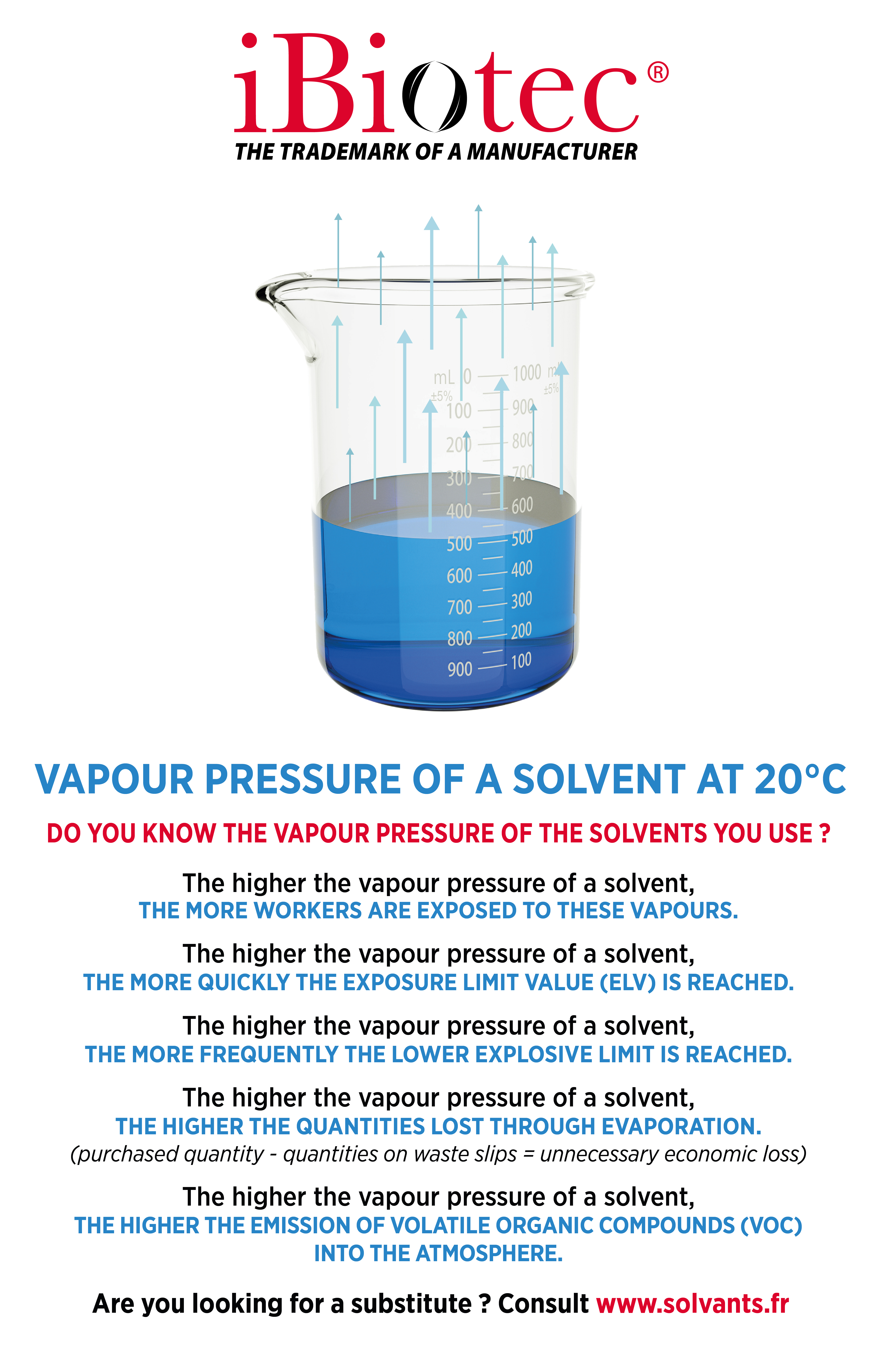

Dichloromethane consumption

REDUCE BY A FACTOR

OF 10

Health - Flammability

Environment

100 % SAFE

|

|

|

RINSING OF CASTING HEADS AND MIXING CHAMBERS

| FAST CLEAN PU 110 |  |

|

• High saturation rate, remains effective even with a high elastomer load, can be re-used several times.

• Recommended for all compact PU resins, including TDI, MTI, and next-generation NDI quick-set resins, on resins

injected by RIM process whatever the mix distribution pressures, the process times, and the TECAM gel times.

• Usable on PU foam, including skin.

|

VOC 0% |

|

Vegetable-based agrochemical fluid

No hazard pictogram (CLP GHS)

No release of vapour when hot

Non-flammable

Reduces organic vapor emissions to 0%.

(Solvent Management Plan, EU - IED - IPPC Directives)

OECD biodegradable

Storage without retention (labour code – ICPE)

Classified NHIW (non-hazardous industrial waste)

Exceptional operating cost

Low volatility, reduces solvent consumption up to a factor

of 10 compared to dichloromethane.

MODE OF USE ON COMPACT POLYURETHANE DISPENSING MACHINE

Washing cycle after polyurethane flow:

- Air blowing air for 10 seconds

- FAST CLEAN PU 110injection for 3/5 seconds

- Air blowing air for 30 seconds

(These times are given as an indication and may vary depending on the nature of the polyurethanes).

The lost casting called "waste casting" is carried out for several reasons; eliminate residues in the chamber, avoid air bubbles, be able to mix again polyols and isocyanates, possibly dyes, homogeneously.

During the washing cycle, the mixing chamber can be positioned above a drum equipped with a funnel to collect the FAST CLEAN PU 110 effluent, and this can be filtered (6/10th millimetre metal filter); the mixture can also be decanted for 24 hours.

FAST CLEAN PU 110 can thus be reused up to 4 times in a row (depending on the polyurethanes).

FAST CLEAN PU 110 can also soak clean compact polyurethane residues or polymerised foam, even with a short Pot Life.

Creation of double glazing joints:

Spatulas are cleaned by simple dipping and paint guns by circulating.

Precautions for use:

Store in a temperate (frost resistant) environment before use.

FAST CLEAN PU 110 is compatible with PTFE seals (tests at 20°C, 80°C and 100°C) and silicone seals.

Avoid use on Neoprene, Buna, Nitrile, Butyl or Viton seals.

YOU CAN PRINT THE FULL FAST CLEAN PU 110

technical data sheet by visiting:

www.solvantspolyurethanes.com

RINSING OF POTTING HEADS

NEUTRALENE 2015

• Suitable for rinsing mixing chambers and for potting resin castings.

• Also suitable for rinsing casting heads, for compact and foam polyurethane resins when there is no pre-casting.

| YOU CAN PRINT THE FULL NEUTRALENE 2015 technical data sheet by visiting: www.degraissantpuissant.com |

|

STRIPPING OF MOULDS AND INSERTS

| FAST CLEAN STRIPPER |  |

|

• Stripping of casting heads |

|

YOU CAN PRINT THE TECHNICAL DATA SHEET BY VISITING

www.solvants.fr

CIRCUIT INERTING

| FAST CLEAN ISO |  |

• Inerting during an extended shutdown

• Rinsing of circuits including isocyanate circuits

• OECD biodegradable